Without a spark there’s no ignition, and without a coil there’s no spark. The coil transforms a low voltage input into the kilovolt (kV) – a unit of electric potential – needed to arc between the spark plug center wire and ground electrode.

Quality coils are essentially fit-and-forget, aiding efficient combustion under all loads and operating conditions for many millions of cycles. In contrast, an inferior coil will, sooner or later, struggle to deliver the voltage and arc duration necessary. The resulting misfires, rough idle and potential emission problems will lead to complaints, warranty claims and damaged reputations.

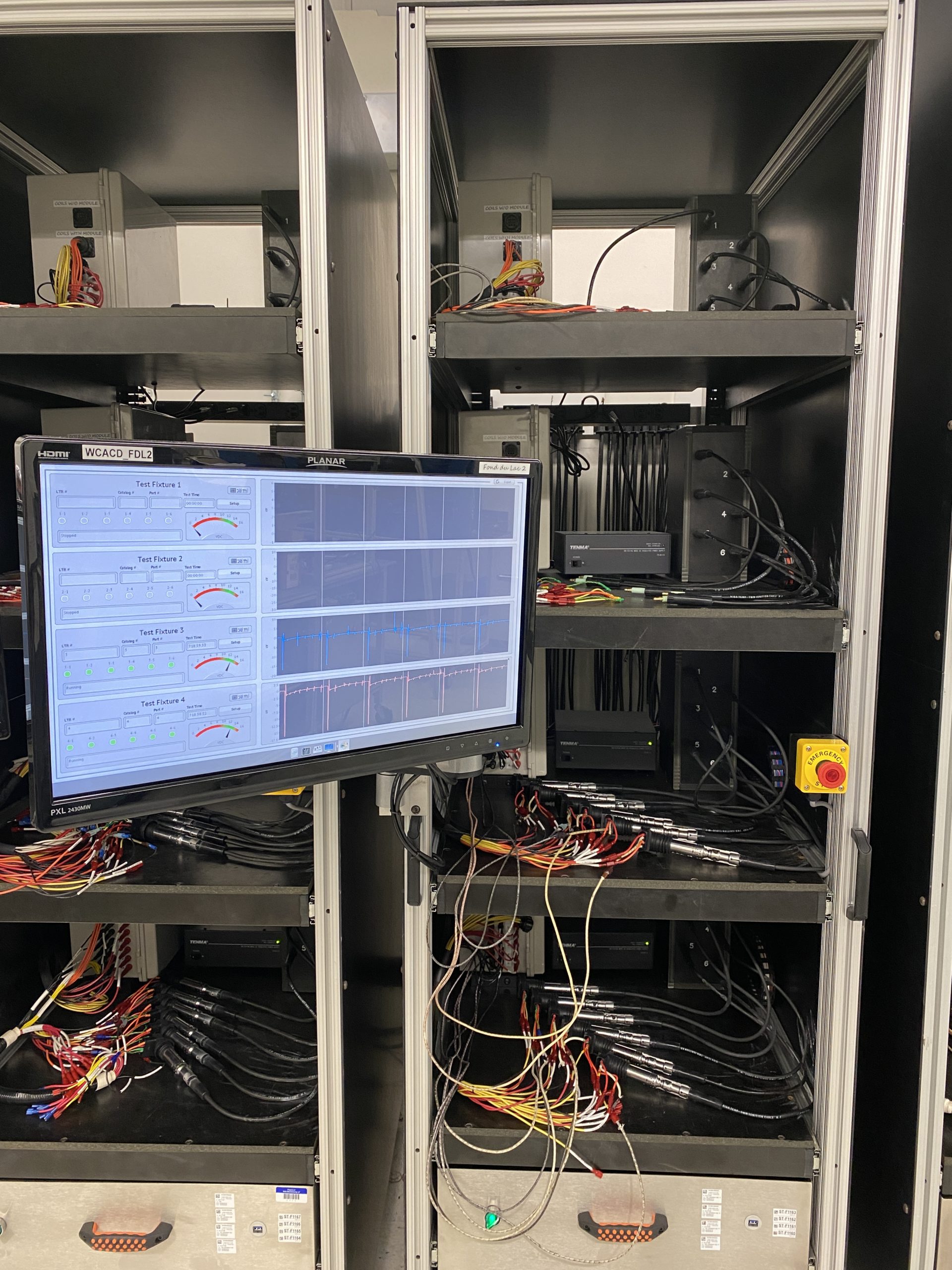

At Wells Engineered Products we don’t take chances on the quality of our coils. We test them, under realistic conditions. We test them during development, we test again for validation, and we do even more testing in production. Some might call it overkill: we call it being thorough.

Coil Operation

To understand the tests we perform, and why they matter, you need to understand how ignition coils work. For anyone who’s forgotten, here’s a very brief primer.

Low voltage current flows through a primary coil. Wrapped around an iron coil, this creates a magnetic field.

At a signal from the computer – or the distributor on a very old engine – the primary current stops flowing. The magnetic field collapses with the change in flux, inducing voltage in a secondary coil. This secondary has many more windings of copper wire than the primary, thereby multiplying the voltage many times over.

The kV of energy built up in the secondary windings forces electrons across the spark gap. The resulting intense heat ignites the fuel-air mixture. Or that’s the theory.

The five tests we perform verify each aspect of this process. For each one, we apply input conditions and measure the outputs. Those inputs could be selected to make the coils appear robust and reliable. Alternatively, they could be chosen to reflect real-world conditions. The latter approach is the only way to ensure a coil will deliver sufficient kV for a long enough time to get a clean, efficient burn. It’s how we do it at Wells Engineered Products.

The 5 Essential Tests

#1: Primary Current Charge Rate

This is a measure of how quickly the magnetic field grows when the primary coil is energized. (The field doesn’t appear at full strength instantaneously due to inductance in the coil.) Primary current should rise linearly over a few milliseconds – the “dwell” time – with the rate of rise being measured in amps per millisecond (A/mS).

This test verifies the coil’s ability to build the target magnetic field, producing the correct output, within the target time. It’s used during R&D, for product validation and as a QC test during production. It’s value hinges on having the correct input conditions, or dwell table, for the intended application. Using an inappropriate dwell table could make a poor-quality coil look better than it is.

#2: Secondary Output Voltage

The coil’s job is to produce enough voltage to create an arc across the spark plug gap. This test measures exactly that property and is performed during R&D, for product validation and as a QC test during production. (Target values can be from 40 to 80kV, depending on coil design.)

As with the Primary Current Charge Rate test, using input conditions that don’t reflect real-world operation will yield misleading results.

#3: Secondary Duration

A second requirement for ignition is that the spark is sustained long enough to start the fuel-air mixture burning. This test measures the time, in microseconds, over which voltage from the secondary coil is delivered to the spark plug. We conduct this test as part of our R&D activity and to validate product performance. It’s not a test we use in production though, as Primary Current Charge Rate Secondary Output Voltage are sufficient for confirming conformance to specifications.

Again, getting meaningful results requires that the input conditions reproduce what the ignition system will see in service.

#4: Secondary Energy

Another test for characterizing the ignition spark, this is performed in R&D and product validation but not as a QC test. Secondary energy is measured in millijoules (mJ). As with the other tests, garbage in, garbage out, or more technically, useful results require a dwell table that accurately reflects actual usage conditions.

#5: Durability

Customers want to know how long their Wells Engineered Products coil will last. Those concerned about their reputation in the marketplace want life to far exceed the warranty period! To establish conservative estimates of coil life we subject them to a proprietary accelerated testing regimen, that is much more strenuous than competitors. This replicates conditions far more arduous than anything they should see in the field, (and harsher than what competitors use.)

Our durability testing is conducted for R&D and validation purposes, not as a production QC check.

Validated Performance for the Real-World

At Wells, we’d argue the coil is the key component of every ignition system. If it can’t deliver the required performance the engine won’t run, and the reputation of its manufacturer will suffer.

The testing we undertake ensure every Wells Engineered Products coil will meet performance expectations, not just when new, but for many millions of cycles. It’s essential to perform the right tests, as detailed here, but it’s just as important to ensure the right test conditions are employed.

Any coil can look good on paper if you test under the wrong conditions. We pride ourselves on using input conditions that reflect actual operating conditions. When you buy our ignition coils you can be confident that the test data reflects how they’ll perform out in the real world.