It takes time and money to add manufacturing capacity, and usually a lot of both. That’s a problem when new business is conditional on meeting tight deadlines. Then what about the customer who needs new features adding to an existing product, but has a fixed launch date? The simple fact is, installing new machines, debugging new processes and ramping up output is difficult, expensive and takes time. But customers don’t want to hear that, which is why you should consider custom manufacturing for your next big opportunity.

Custom manufacturing, as we use the phrase here at Wells Engineered Products, means having exactly what you need made for you. Instead of selecting processes, deciding on the appropriate level of automation, finding space and writing countless checks, the custom manufacturer does that for you. They make your product on their machines, in their factories, using their proven processes. Curious how that works? Then read on.

When Opportunity Knocks, Can You Respond?

Your customers are locked in ferocious competition with their rivals. They need you to supply them with higher-performing, next-generation products packed with new features and capabilities. Trouble is, you can’t create those overnight. Common roadblocks include:

- The new product includes features which you lack the production equipment or technical competency to incorporate.

- New quality demands require manufacturing capabilities you don’t have.

- You don’t have the capacity to take on new business.

- You can’t ramp up production in time to meet demand.

- The product lifecycle is unknown or may be too short for an attractive return.

None of these are insoluble. The problem is that the solutions involve risk and have major implications for cashflow. Or to put it another way, your finance people don’t have unlimited money and are likely very risk-averse.

What A Custom Manufacturer Can Do for You

The custom manufacturer we’re referring to here is of course Wells Engineered Products. Our expertise is in producing precision engine management and power control products. These go to manufacturers of premium off-road, marine, agricultural, motorcycle, power generation and industrial equipment.

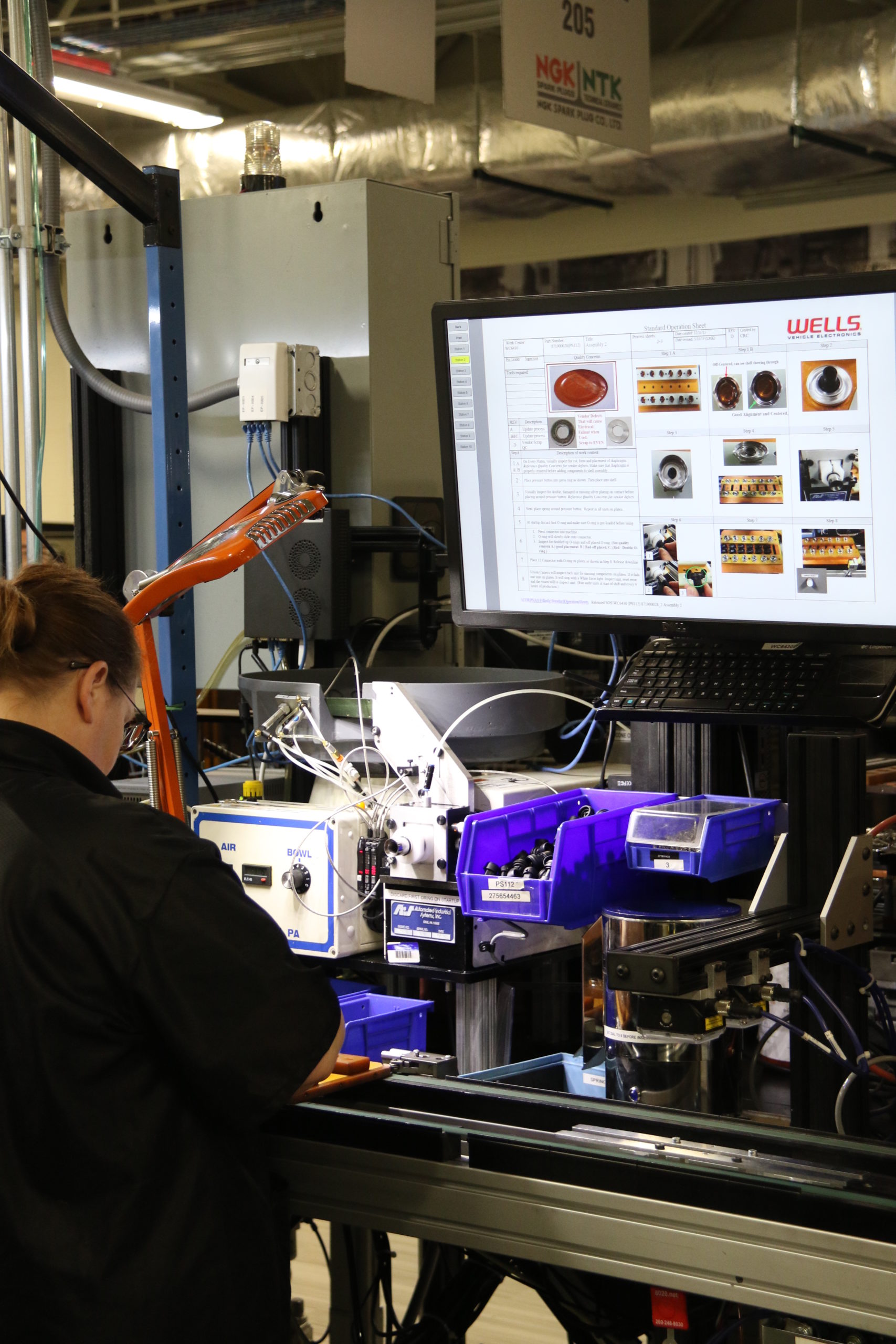

Our manufacturing capabilities range from plastic injection molding to ceramic substrate motor controllers and hybrid thick-film circuits. We’ve invested heavily in highly flexible automated manufacturing utilizing advanced robotics and machine vision. Those give us the flexibility to produce in lower as well as high volumes, and we can incorporate serialization for traceability when needed.

Our product engineering expertise is equally impressive. More than 50 electrical design, mechanical design and manufacturing engineers have access to facilities like

- Analog and digital electrical circuit simulation

- Finite Element Analysis (FEA)

- Thermal modeling and analysis

- 3-D printing

- ISO 17025-certified Validation and Testing laboratories

Imagine what a difference it would make if we put those resources to work on your behalf.

Saving Time and Money with Custom Manufacturing

Why start from scratch when you can work with a company as capable and well-resourced as Wells Engineered Products? Our goal is to be your partner in creating premium customized product solutions. Here are 9 ways in which that will benefit your business.

- Get to product launch in less time. The manufacturing capacity is already in place. It’s proven and working. Eliminating the time needed for equipment to be built, delivered, installed and accepted can cut months out of the schedule and give you a major advantage over your competitors.

- Avoid substantial capital expenditures. Manufacturing equipment can be extremely expensive, especially when challenged by tight tolerances and expectations of low variability. When you partner with a custom manufacturer that equipment is already in place and operational.

- No learning curve effects or training requirements. Add a new process to your factory and everyone has to learn how to use it and work on it. This isn’t just operators, but engineers, maintenance techs, even supervisors and QC staff all need time to understand and get the best from something they’re unfamiliar with.

- Free engineering resources to work on other projects. Installing capacity and starting-up production of a new or different product consumes many engineering hours. Working with a custom manufacturer has the effect of growing your engineering team, letting your staff address other problems and opportunities.

- Avoid costly building additions. When there’s no space left in the factory, expanding capacity usually means adding-on to the building. That’s expensive, pushes production start-up out by a few months and can get you into a host of regulatory issues. Then there’s the risk that, should business contract you’re left with an empty space to heat, cool and pay taxes on. Partner with a custom manufacturer and that’s their problem, not yours.

- No environmental, health & safety “gotchas” to catch you by surprise and add unforeseen delays to the project. This is a particular risk when implementing new cleaning, joining or finishing processes. Chemicals and fumes can pose a host of problems which, if you’re not familiar with the process, can require costly management and mitigation.

- No quality surprises. When starting to make a new product or one with features you’re not familiar with, there’s a risk of unexpected quality problems. A custom manufacturer has probably seen these before and knows what preventative actions to take.

- No recruitment needs. Particularly when the labor market is tight, hiring people can be difficult. Plus, they will need onboarding and training. Avoid that time and expense by letting the custom manufacturer handle it.

- Ability to take on projects and products with a short life. When you install new capacity, finance expects it to be utilized for many years to come. The precision engine management and power control products markets sometimes offer up shorter-term opportunities: a custom manufacturer can help.

Become More Agile with a Custom Manufacturing Partner

Matching manufacturing capacity to a complex and dynamic market is extremely difficult. Most manufacturers have difficulty in ramping up production or switching between products quickly enough to take advantage of opportunities that may be available. Partnering with a custom manufacturer provides a solution that saves time and money while increasing your agility.